The “extended workbench” in plant engineering: How modern production methods secure a competitive advantage

In plant engineering, efficiency, flexibility, and reliability are crucial to meeting the challenges of today's markets. A proven solution that enables companies to meet all these requirements is the "extended workbench" concept . This is a partnership in which an external service provider acts as an extension of the company to outsource specific manufacturing processes. This concept enables companies to expand their production capacities without having to invest in additional resources or infrastructure themselves.

Cost reduction and efficiency increase

By partnering with a specialized service provider that has the necessary expertise and infrastructure, companies can streamline their production processes while simultaneously reducing costs. External partners not only contribute their expertise but often also offer modern technologies and solutions that aren't available internally. This leads to better resource utilization and reduced production costs.

Flexibility and scalability

Using an external partner as an "extended workbench" provides enormous flexibility. Companies can adjust their production capacities as needed without entering into long-term commitments or investing in expensive infrastructure. This is particularly advantageous when companies operate in a dynamic market environment where demand and requirements change rapidly.

Access to modern manufacturing techniques and technologies

An external partner acting as an "extended workbench" can also provide access to cutting-edge technologies that the company itself might not be able to utilize to the desired extent or at the right time. This is where concepts such as lean manufacturing , predictive maintenance , modular production units , and automated manufacturing processes come into play. These innovative approaches not only contribute to increased efficiency but also to error reduction and optimization of production processes.

Integration of Supply Chain Management (SCM)

Another advantage of the "extended workbench" is the close integration of supply chain management and manufacturing. The partner not only handles production but also optimizes logistics and material flow. This ensures that the right materials are in the right place at the right time, leading to even more efficient project execution.

Predictive maintenance and efficiency optimization

By integrating predictive maintenance, companies can ensure their equipment is always operational. An external partner can help integrate these technologies into production, ensuring equipment is serviced in a timely manner and preventing unexpected downtime.

Modularization and just-in-time production

Modularization allows for the use of standardized components that can then be assembled into more complex systems as needed. Combined with just-in-time and Kanban methods, companies can further optimize their production processes. These methods help ensure that only the required parts are produced in the right quantity and at the right time, reducing inventory costs and production times.

Digital networking and cloud-based platforms

Modern cloud-based manufacturing platforms enable the entire production chain to be monitored and controlled in real time. Companies and their partners can access current production data at any time, make changes, and optimize production. This digital networking makes it easier to respond quickly to market demands and improve production processes.

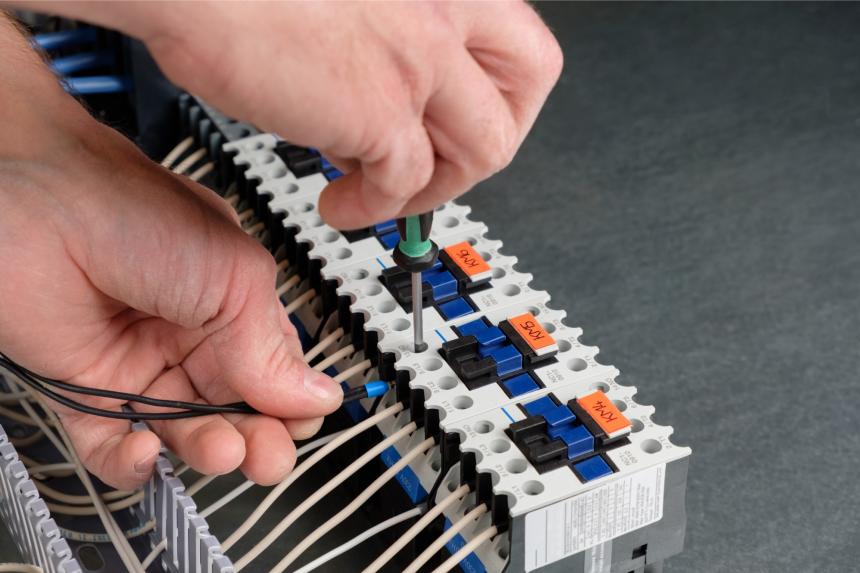

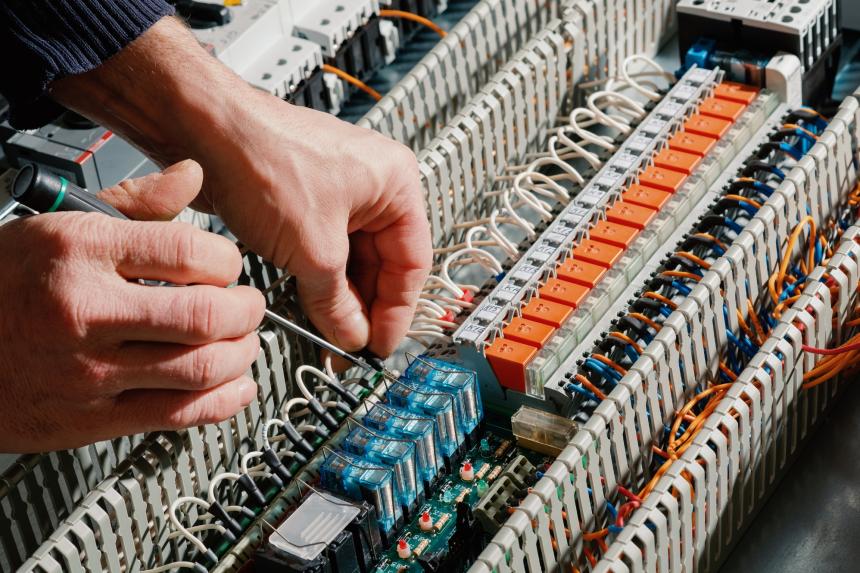

The extended workbench in control cabinet construction

The concept of the extended workbench makes particularly good sense in control cabinet manufacturing. Plant manufacturers can outsource many production processes, such as control cabinet construction, and benefit from specialized partners like WIMTECH. By utilizing the partner's infrastructure, such as their warehouse capacity and manufacturing resources, storage costs can be reduced while simultaneously shortening production times.

In addition, plant manufacturers can draw on their partner's expertise in control cabinet construction to optimize their own manufacturing processes. The partner offers not only technical expertise but also customized solutions that enable complex requirements to be met quickly and efficiently. This flexibility helps plant manufacturers focus on their core competencies while maximizing the quality and precision of their products.

By partnering with a specialized service provider in control cabinet construction, plant manufacturers can benefit from high quality and efficiency without having to invest in expensive infrastructure or additional personnel.

How WIMTECH acts as an “extended workbench” in plant engineering

At WIMTECH, we offer our customers the opportunity to benefit from all of the advantages mentioned above. As your partner in plant engineering, we handle mechanical and electrical assembly , control cabinet construction , and contract manufacturing of complex assemblies. We not only act as an external service provider, but also integrate seamlessly into your existing production processes and provide you with customized solutions that increase your efficiency and flexibility.

Our customers not only benefit from our extensive know-how and experience, but also have access to our in-house infrastructure to implement their projects quickly and reliably. Our Perforex milling center and our in-house testing area ensure the high quality and precision of our work. We also offer you the option of using our intermediate storage facilities for even more flexible project execution.

Through close collaboration, we can ensure that you not only receive high-quality results but also have the flexibility to adjust your production capacities as needed. Our ISO-certified processes and our focus on safety and efficiency guarantee that your projects are always completed on time and within budget.

With WIMTECH as your partner within the framework of the “extended workbench”, you secure a competent and reliable service provider who not only expands your capacities but also develops the best solutions for your projects together with you.

„We think like our customers – and act like their own department.”

Contact us

With our know-how in the areas of plant engineering and electrical engineering, the necessary human resources and a global network, we are ready for your project!