As a service provider for companies in the field of conveyor technology, we naturally deal intensively with the current trends in the industry. Although the year 2024 brings with it some challenges for many companies due to economic developments, there are still numerous opportunities and exciting opportunities for innovative companies.

Technological advances in conveyor technology - AI & Co

The materials handling industry is going through a phase of groundbreaking technological developments, with the digital transformation of processes playing a key role. The use of AI-supported systems for data analysis offers revolutionary possibilities for optimizing and controlling the new generation of conveyor technology systems. In predictive maintenance , AIs plan system maintenance based on data collected by sensors. In this way, potential problems can be identified and resolved at an early stage in order to avoid costly downtimes and significantly extend the service life of the systems.

IoT as a game changer in the industry

The Internet of Things (IoT) is also becoming increasingly important in the conveyor technology industry. By connecting devices and systems, companies can monitor the status of their conveyor systems in real time in order to efficiently control material flows. In addition, the IoT opens up new opportunities for optimizing logistics processes and supply chains.

Automation for more efficiency

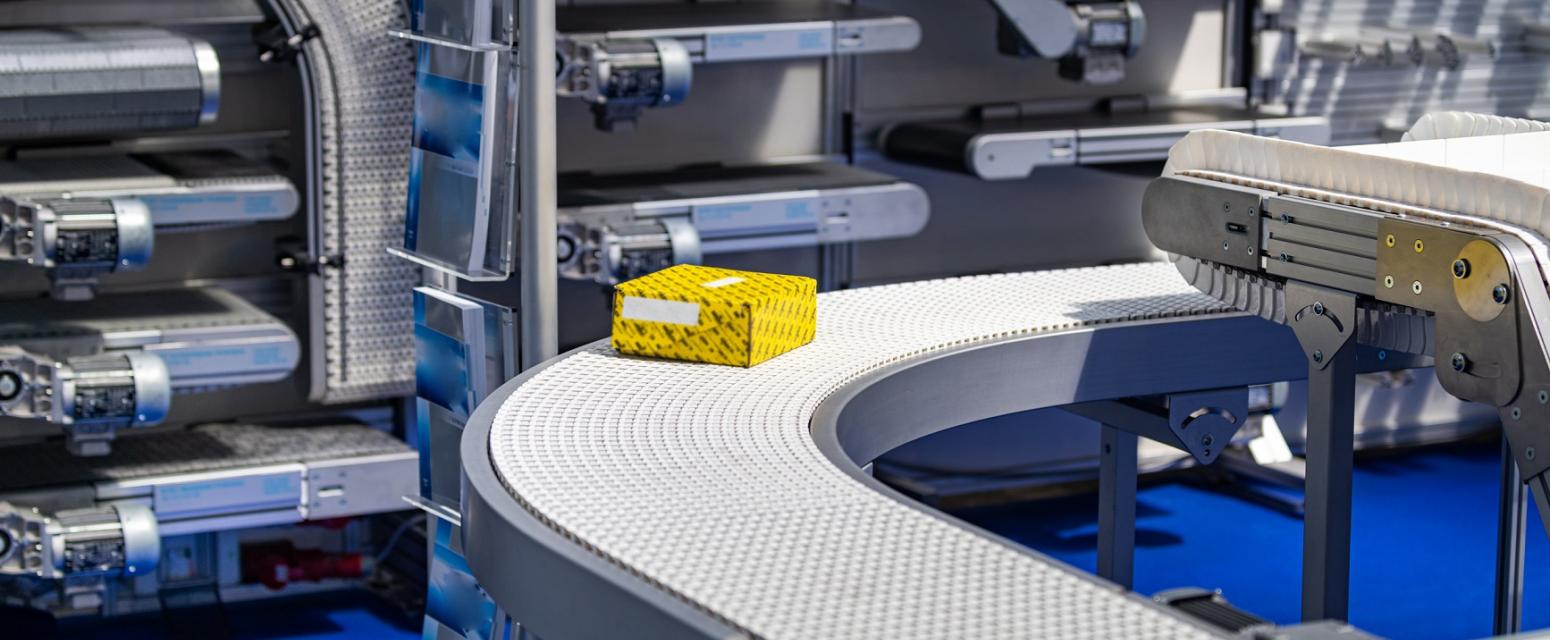

More and more companies are relying on automated conveyor systems to make material flow more efficient and conserve resources. Robots are playing an increasingly important role, be it in palletizing, order picking or even the completely autonomous operation of conveyor lines in production. In this way, companies can control their production processes precisely and react quickly to new production requirements.

Sustainability and environmental awareness

In view of growing environmental problems and the pressure to reduce CO2 emissions and work in a way that conserves resources, environmentally friendly production solutions are becoming increasingly important. The integration of energy-efficient drives, the use of renewable energy sources and the optimization of processes to avoid waste are just a few examples of how the industry of the future can minimize its ecological footprint.

Globalization and supply chain management

Globalization has had a major impact on the conveyor technology industry and will continue to do so in 2024. The increased networking of markets opens up many opportunities but also challenges for companies. Effective supply chain management and flexibility are critical to adapt to rapidly changing geopolitical conditions.

This is how we at WIMTECH deal with the new requirements of the industry

One of the biggest challenges is the ongoing labor shortage and the increasing need for highly qualified specialists with knowledge of the use of new technologies and working methods.

Despite the advent of AI systems, automated systems and the IoT, people remain the most important resource at WIMTECH. What changes are the tasks and the required know-how of the specialists in order to be able to use the full potential of the new technologies. In the area of personnel development, we therefore focus on targeted further training for our employees and supplement our team with specialists from the required specialist areas.

We have a global network of suppliers and partners, as well as specific know-how in handling international assembly projects. This allows us to respond flexibly to our customers' requirements and support them as they enter international markets.

We are convinced that the key to sustainable success lies in the ability to change. The time of rigid structures and entrenched working methods is finally over. Only those who can react quickly to the needs of their customers, design internal processes in an agile manner and work with the latest technology will remain competitive in the long term. We work according to modern project management methods and rely on flat hierarchies in order to be able to react quickly and flexibly to customer requirements.

In order to be able to serve our customers holistically, we not only adapt our working methods, but also our service portfolio. In addition to international assembly projects and control cabinet construction, we also undertake the assembly of complex assemblies and system components in our in-house contract manufacturing.

„We look forward to the future positively and are convinced that even in challenging times there is always room for innovative companies, not just in the conveyor technology industry.”

Contact us

With our know-how in the areas of plant engineering and electrical engineering, the necessary human resources and a global network, we are ready for your project!